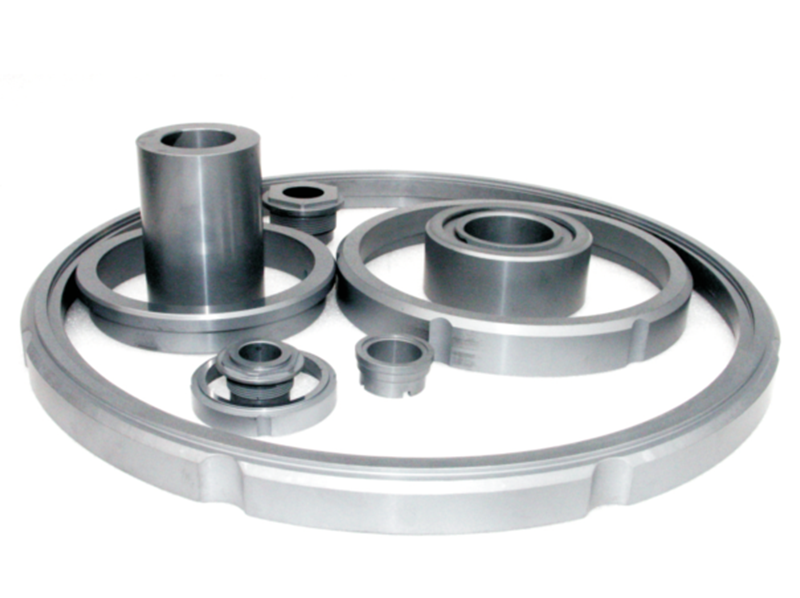

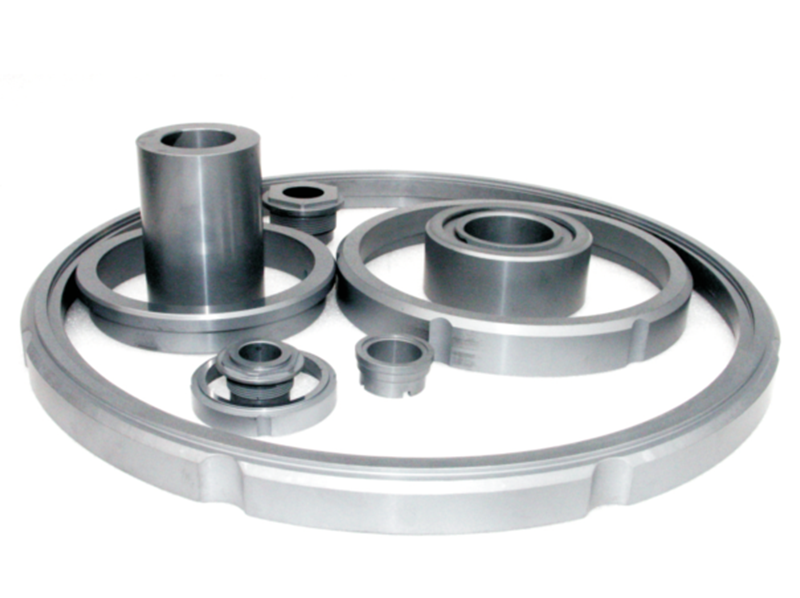

Reaction bonded sic is sintered by adding the free silicon (content is less than 12%) into the reaction sintering sub-micron silicon carbide powder in 1500C vacuum sintering furnace. Under high temperature, the free silicon reaction enhances its lubrication performance and reduces its friction coefficient and therefore strengthens the characteristics of wear resistance and malleabilty. The maximum overall sealing ring can be as big as 580 mm. So it is widely used in the bearing, petroleum, chemical, motors, ships and pump valve industries.

项目 Operating Limits | 单位

Units | 反应烧结碳化硅

(RBSIC) |

体积密度

Volume Density | g/cm3 | ≥3.03 |

维氏硬度

Vickers Hardness | HVO.5 | ≥2000 |

洛氏硬度

Rockwell Hardness | HRA | ≥90 |

显气孔率

Indicated Porsity | % | <0.2 |

抗压强度

Compression Strength | Mpa | ≥2000 |

弯曲强度

Transverse Strength | Mpa | ≥350 |

弹性模量

Elastic Modulus | Gpa | ≥350 |

导热系数

Thermal Conductivity | W/m*k | 30-130 |

最高使用温度

Maximum Temperature | C | 1000 |

热膨胀系数

Coefficient of Heat Expansion | 10-6*1/°C | 4.0-5.0 |